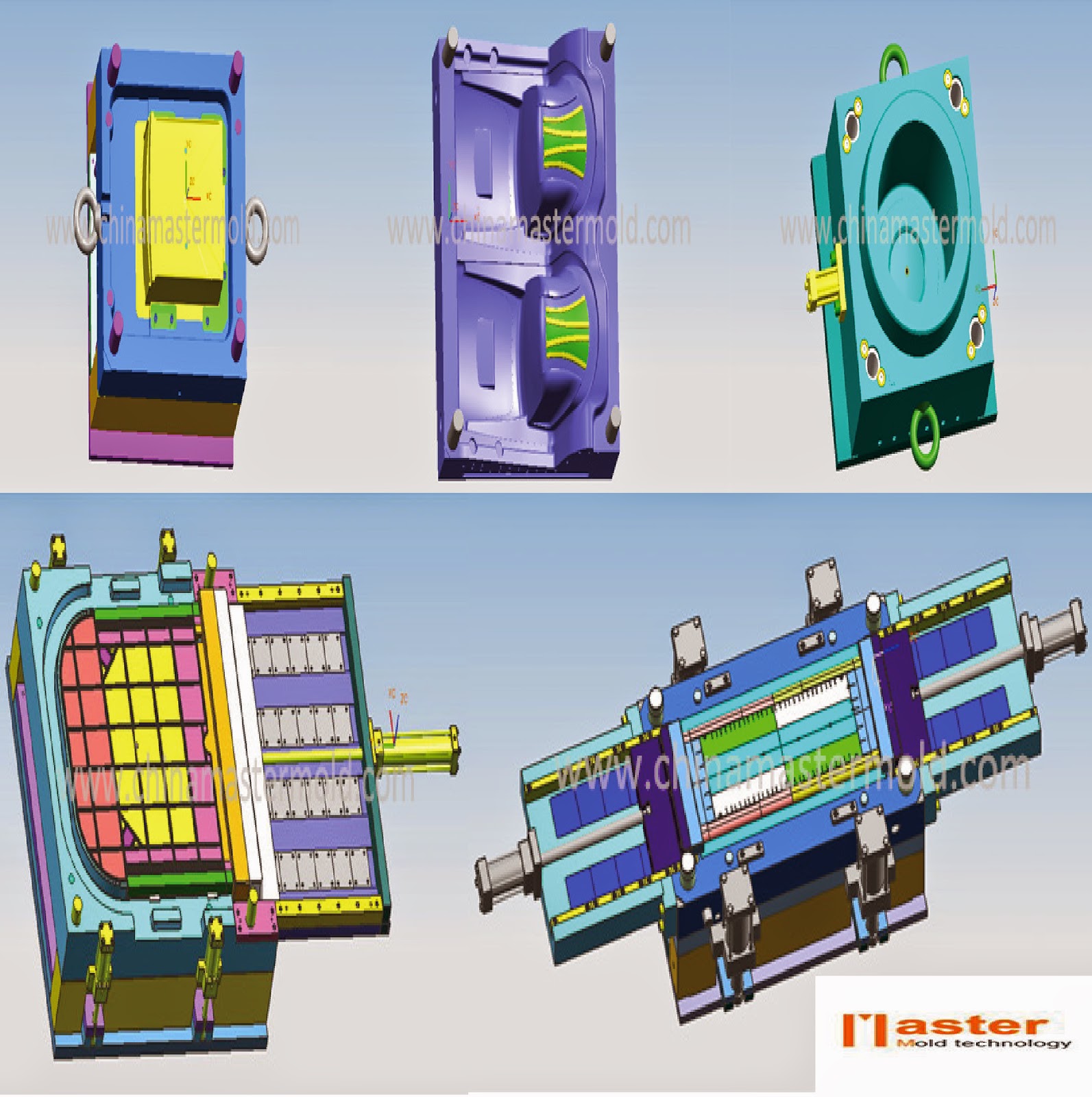

MASTER Mould is Chinese professional plastic mold company,manufacturer, supplier and maker. We has manufactured number of Chair moulds every year. The latest technology with our experienced designer keep our ahead in the plastic moulding industry, We adopt 3D scanner to obtain accurate Chair dimensions, and the latest 3D platform assist us to build the most reliable 3D model, Plus advanced CNC equipments. It's the key for us to provide out stand MASTER chair mould.

Use household plastic rattan garden furniture, balcony, office, hotel, restaurant, gardens, squares, schools, hospitals, villas, entertainment and leisure venues.

2015年12月29日星期二

2015年12月25日星期五

MASTER plastic mould order

We carry injection moulds for MASTER plastic injection mould chairs, baby chairs, plastic garden and outdoor furniture including tables, racks, trolleys, plastic cabinets and other plastic furniture. Our company’s focus is to keep improving to supply satisfied mould and circumspect service. A partial list can be viewed on the links (MASTER plastic mould). If you have a specific requirement for plastic injection moulds or manufacturer of molds and dies for plastic furniture then please write to us at sales@chinamastermold.com

2015年12月21日星期一

Keeping furniture mould in storage for long periods of time

In humid conditions, mold and mildew can thrive on leather, wood and upholstered furniture. Over time, these fungi can reduce the aesthetic value of furniture and give off an unpleasant, musty odor. Cleaning and preventing MASTER plastic rattan garden furniture mold and mildew growth will eliminate these problems, as well as protect your family against harmful allergens. So you must Keeping furniture in storage for long periods of time decreases the likelihood of mold and mildew growth. Plastic Rattan Imitation series is our new project which has good reputation all over word,especially for the rattan imitation garden MASTER chair mould,table,sofa,etc. Plastic rattan garden furniture is widely used instead of hand-made rattan furniture because of many advantages,like UV-resistant, efficient production,light weight and lower cost.

2015年12月17日星期四

pigment and other additives

Custom plastic mold The main component is a resin plastic. The term was originally resin secreted by the animal and plant lipids named,plastic drawer mold closed moldhigh fever, plastic moulders high pressure in the plastic It was softening viscous flow, after a certain time curing stereotypes, into a desired shape of the article. plastic mold manufacturer made of a synthetic resin filler, a plasticizer, a stabilizer, a lubricant,cabinet mould pigment and other additives.

2015年12月13日星期日

mold making Good impact resistance

mold making Good impact resistance; insulation, and low thermal conductivity,Plastic pallet mould Versatility, plastic container

molding utility and more easily colored, some high temperature,plastic moulders Most of the good insulator, light weight and strong ,MASTER thin

wall injection molding china plastic mold Easily processed mass production, cheap

2015年12月9日星期三

Custom injection moulding

Custom injection moulding The term was originally resin secreted by the animal and plant lipids named, such as rosin, shellac, resin and various additives that have not yet mixed polymers. injection moulding companies Accounting for the total weight of the plastic resin, the basic properties of plastics depends mainly on the nature of the resin,Make plastic molds General moldability, good color, low processing costs,plastic mould maker Most plastic poor heat resistance, thermal expansion coefficient, injection

mold maker easy combustion,Poor dimensional stability, easily deformed

2015年12月5日星期六

china plastic injection molding

china

plastic injection molding the movable die is mounted on the movable platen injection molding machine, scheduled to die is mounted on the stationary platen injection molding machine.In the injection molding of the movable die and the fixed mold casting system and constitute a closed cavity mold when the pvc pipe fitting

mould movable die and the stationary die separation to remove plastic products.

2015年12月1日星期二

Injection molding

Injection molding, the mold clamping on injection molding machine, molten plastic is injected into the mold cavity, plastic injection toy

mould and the cavity cooling setting, then the upper and lower split die Via the top of the article from the mold cavity will leave the top of the mold, the mold is closed again for the next injection, plastic

injection toy mould the whole cycle of the injection molding process.General plastic mold by a movable mold and the fixed mold composed of two parts

2015年11月27日星期五

this combination successful mold cavity

The rapid development of the plastics industry and general engineering plastics in strength and precision, has been improving Range of applications in the expanding plastics, mold making plastic products rapidly increasing proportion of positive A well-designed plastic parts can often replace the more conventional metal. The amount of plastic products is on the rise.Plastic mold is a plastic tool production.It consists of several groups of components parts, injection mold

maker this combination successful mold cavity

2015年11月23日星期一

Plastic pallet mould

Convex mold, coordinated and assisted molding die change systems.Machinable different shapes, Plastic pallet mould different sizes of plastic parts series.Plastics processing industry and the plastic molding machine supporting, giving plastics to complete configuration and precise dimensions of the tool.Since many plastic varieties and processing methods, structural plastic molding machines and plastics and simplified vary, plastic

rattan garden furniture mold so kind and structure of the plastic mold is varied.

2015年11月19日星期四

A method for compression molding

A method for compression molding, extrusion, plastic rattan

garden furniture injection molding, blow molding and foam molding low modular plastic mold It includes a combination of a substrate by a die, die components and die combination card panels Die having a variable cavity by punch combinations substrate, garden plastic chairs

mold the punch assembly punch combo card board, cut side cavity truncated components and combination plates Having a variable core punch.

2015年11月15日星期日

MASTER injection mould

Three are: current, PVC pipe development

in the high-speed development period, industry capacity expansion, many

small and medium enterprises to seize the market, reduce costs, MASTER pipe fitting mould

a lot of filling in the formulation of calcium carbonate, shoddy,

affecting the PVC pipe industry's image direct impact on the PVC market

share, accelerate the loss of PVC market share.

But overall, although PVC pipe share declining, but still occupy the dominant position of plastic pipe market. MASTER injection mould And tantalizing prospect of plastic pipe industry is still driven by the development of a major highlight of PVC pipe industry.

But overall, although PVC pipe share declining, but still occupy the dominant position of plastic pipe market. MASTER injection mould And tantalizing prospect of plastic pipe industry is still driven by the development of a major highlight of PVC pipe industry.

2015年11月12日星期四

MASTER pot mold

Injection molding is a batch processing method used when certain

parts of complex shape. Specifically refers to the material by the high

heat to melt, into the mold cavity, after cooled and solidified to

obtain a molded product. Is a plastic injection mold tool production;

also given plastic structural integrity and precise MASTER molds for plaster dimensions of the tool.

Injection mold according thermoset molding characteristics divided into plastic molds, plastic molds thermoplastic two kinds; according molding process is divided into transfer molding, blow molding, cast molding, thermoforming mold, heat dies (pressure mold), injection molding, etc. MASTER pot mold which heat dies in flash mode can be divided into overflow

Injection mold according thermoset molding characteristics divided into plastic molds, plastic molds thermoplastic two kinds; according molding process is divided into transfer molding, blow molding, cast molding, thermoforming mold, heat dies (pressure mold), injection molding, etc. MASTER pot mold which heat dies in flash mode can be divided into overflow

2015年11月9日星期一

MASTER custom plastic mold

MASTER plastic molding factory

Plastic injection mold makers semi-overflow-style, does not overflow

type three, injection molding to casting system can be divided into cold

runner mold, hot runner mold two kinds; way to press handling can be

divided into mobile, fixed two.Gating system, also known as the

runner system, it is the plastic melt from the cavity injection machine

nozzle toward a group of feed channels, usually by the sprue, runner,

MASTER custom plastic mold gate and cold slug components. It is directly related to the quality and

productivity of molding plastic products.

2015年11月6日星期五

MASTER plastic drawer mold

Industry analysts pointed out: PVC complete industrial chain and

supported by the domestic raw materials, PVC pipe production in 2010

accounted for 55% of the total. In recent years, PVC pipe market is

affected by various factors in the continuing decline in its market

share. The PVC pipe market share decline has three MASTER molds for plaster major areas:Plastic injection mold makers,First: PVC pipe market impact of other plastic pipes PE, PPR, etc., is to seize some market share;The

second is: Disabled leaded stabilizers in contact with food products in

PVC pipe, MASTER plastic drawer mold there is a negative impact on the development of PVC pipe

2015年11月3日星期二

MASTER plastic mold manufacturer

china plastic injection molding PVC profile products experienced a

period of rapid development and introduction period from the time point

of view, can be defined as the mid-1980s -90 twentieth MASTER plastic mold manufacturer century and around 1995 to 2002. After 2003, PVC profile industry entered a transition period. Import of products: Manufacturer common pursuit of low cost, MASTER plastic injection mould

simplified window profiles section, filled with a lot of calcium

carbonate formulations, resulting in low performance, a lot of quality

problems affected the promotion of the product.

2015年10月31日星期六

plastic container molding

injection mould design according to the characteristics of thermosetting

plastic mold divided into thermoplastic plastic mold two kinds,process is divided into transmission mold, blow molding, cast molding,

thermoforming mold, heat dies (pressure mold), injection molding,

etc. which heat dies in flash mode can be divided into overflow,

semi-overflow-style,plastic container molding does not overflow type three, injection molding to

casting system can be divided into cold runner mold, hot runner mold two

kinds; taken by way of handling can be divided into mobile, fixed two.

2015年10月28日星期三

plastic mould maker of the cavity before entering the flow path

Gating system refers to the plastic from the nozzle portion plastic

mould maker of the cavity before entering the flow path, including the

main channel, cold-slug, diversion channel and the gate and so on.

Forming part refers to the shape of the various parts constituting

products, including dynamic simulation, the fixed MASTER cabinet mould mold and cavity, core, forming rod and exhaust ports and so on. Under

the impetus of plastic mold and pillar industries of high

technology-driven application requirements, forming a huge industrial

chain, from upstream raw material industry and MASTER egg tray mold

processing, testing equipment to the downstream machinery, automobiles,

motorcycles, home appliances, electronic communications , building

materials and other major application industries, plastic mold

developing a life

2015年10月25日星期日

A professional plastic mold manufacturer

plastic mold manufacturer When the pressure is not deformed afford the smaller the better, can be

avoided to avoid empty space where, to reduce weight of the mold.

Fourth, processing technology, all of columbium and parts to be heat

treated roughing, allowance is generally unilateral stay between

0.25-0.5mm; 2, even after heat treatment workpiece drawing back to the

grinder together, the workpiece shape and by the number of right-angle

grinder to grind. As for the plastic processing is not difficult to

impose planes reserved 0.15mm province mill; 3, finishing the workpiece

by the grinding machine,injection mold maker the first self-test, and then to detect mold

QC, OK before they can be sent to the CNC lathe.

2015年10月22日星期四

MASTER mould maker

Mold design one, the design of the mold before the mold is opened first

pop 0.05-0.1mm, easy blowing, to avoid sticking to the former model; 2,

inserts and inserts, inserts and columbium MASTER mould maker

mating surfaces of every mill exhaust ducts number four, according to

the characteristics of the product structure, materials, and beer;, depth

is defined as 0.015mm; 3, carrying water to do the entire mold

reasonable, adequate, with as much as a principle, it should be done

every inserts carrying plastic drawer mold water how many, the MASTER injection moulding companies choice of a reasonable mold material. In the last election material size necessary to bear.

2015年10月19日星期一

plastic moulders It includes photovoltaic

plastic moulders It includes photovoltaic, photochemical generation,

optical sensors and optical bio-four forms of power generation power

generation, there is an electrochemical photovoltaic MASTER plastic container molding cells in the photochemical generation of photovoltaic cells and photocatalytic cell solution.

Solar thermal power generation is the first solar MASTER plastic moulders energy into heat, then heat into electricity, it has two conversion methods. A solar thermal energy is directly converted into electrical energy, such as a semiconductor or metal material generating the temperature difference, the vacuum device and the hot electron plasma thermal power generation, AMTEC, MHD power generation, and the like. Another way is to drive the generator to produce electricity through solar thermal heat engines (such as steam turbines), similar to conventional thermal power generation, but is not its heat energy from the fuel, but from solar energy.

Solar thermal power generation is the first solar MASTER plastic moulders energy into heat, then heat into electricity, it has two conversion methods. A solar thermal energy is directly converted into electrical energy, such as a semiconductor or metal material generating the temperature difference, the vacuum device and the hot electron plasma thermal power generation, AMTEC, MHD power generation, and the like. Another way is to drive the generator to produce electricity through solar thermal heat engines (such as steam turbines), similar to conventional thermal power generation, but is not its heat energy from the fuel, but from solar energy.

2015年10月17日星期六

plastic mould manufacturers

plastic mould manufacturers China's

mold enterprises must actively learn from foreign the experience of

advanced enterprises, so that the development of a better future.

According to the molding material, mold can be divided into hardware

mold, plastic mold, as well as its special mould.Plastic

mold manufacturers include: plastic mold manufacturer stamping die non-metallic mold is divided

into: plastic mold and inorganic non-metallic mold. According to the

mould material, mould can be divided into: sand mold, metal mold, vacuum

mold, paraffin wax mould. Among them, with the r apid development of

polymer plastic, plastic mold and closely related to people's life.

Plastic mold generally can be divided into: injection molding, extrusion

molding, gas assisted injection molding mould.

2015年10月13日星期二

MASTER pvc pipe fitting mould

Custom plastic mold To make solar power truly reached the practical

level, it is necessary to improve the photoelectric conversion

efficiency of solar energy and reduce its costs, and second, MASTER pvc pipe fitting mould to achieve the same solar power grid interconnection.There are monocrystalline silicon solar cells, polycrystalline silicon, amorphous silicon three. Highest conversion efficiency monocrystalline silicon solar cells, MASTER make plastic molds

has reached more than 20%, but the price is expensive. Amorphous

silicon solar cell conversion efficiency of the lowest, but the price is

the cheapest and most have hope for the future generation in general

will be the battery. Once it's a large area components photoelectric

conversion efficiency of 10%, the price per watt of power generation

equipment to $ 1-2, would be sufficient to compete with other power

generation. Estimate of this century we can achieve this leve

2015年10月9日星期五

plastic drawer mold Cold slug diameter of about eight a lOmm

plastic drawer mold Cold slug diameter of about eight a lOmm, depth of

6mm. In order to facilitate mold release, normally borne by the bottom

of the release lever. Top release lever MASTER plaster mold

should be designed to zigzag trench subsidence hook or set up in order

to successfully pull the sprue superfluous matter when stripping. with

an annual output of more than 20,000 tons less than MASTER pvc pipe fitting mould

10 enterprises, product quality is uneven, poor quality products still

have a market, industry quality technical standards too low, is not

conducive to technological progress, leading to substitute aluminum

comeback. The high-end market (30%) were occupied by foreign brands,

middle and low market unprofitable, intense competition, the final

pattern has not yet formed.

2015年7月2日星期四

Pvc pipe fitting mould

Ancient Chinese "Sui" appears as an offering to the vine, the Ming Dynasty Masanori years compiled a "positive Jeannet Taiwan Chi" and subsequent "Cliff Chi Chuan" describes the distribution and utilization of rattan. Quanzhou Museum on Zheng He of the Ming Dynasty preserved shipwrecks rattan furniture, these rattan furniture have confirmed the level of development of China at that time. In the existing fine of Ming and Qing furniture, Water purifier molding there are also a rattan chair seat.

According to the Qing dynasty, published "Yongchang government" and "vault hall" records, western Yunnan Tengchong and other places on the use of rattan can be traced back to the Tang Dynasty, to date more than 1500 years of history; in southern Yunnan, according to the Qing " Yuanjiang House "and Republican" Continued New Annals of Yunnan "records, the use of rattan began in the early Qing Dynasty, so far has been 400 years of history. According to the research, Yunnan rattan before World War II have a higher level. At that time, Yunnan rattan exported to Southeast Asia and Germany and other European countries. Yunnan rattan in rattan Tengchong reputation is highest. Rattan style known as the three best Tengchong, Tengchong history books, also known as the vine, Fujikawa, rattan red, thereby glimpsed, Tengchong of rattan, the Great Hall had it as a collection of treasures.

According to the Qing dynasty, published "Yongchang government" and "vault hall" records, western Yunnan Tengchong and other places on the use of rattan can be traced back to the Tang Dynasty, to date more than 1500 years of history; in southern Yunnan, according to the Qing " Yuanjiang House "and Republican" Continued New Annals of Yunnan "records, the use of rattan began in the early Qing Dynasty, so far has been 400 years of history. According to the research, Yunnan rattan before World War II have a higher level. At that time, Yunnan rattan exported to Southeast Asia and Germany and other European countries. Yunnan rattan in rattan Tengchong reputation is highest. Rattan style known as the three best Tengchong, Tengchong history books, also known as the vine, Fujikawa, rattan red, thereby glimpsed, Tengchong of rattan, the Great Hall had it as a collection of treasures.

2015年6月28日星期日

Garden plastic chairs mold

Ancient Chinese "Sui" appears as an offering to the vine, the Ming Dynasty Masanori years compiled a "positive Jeannet Taiwan Chi" and subsequent "Cliff Chi Chuan" describes the distribution and utilization of rattan.plastic rattan garden furniture mold plastic rattan molding Quanzhou Museum on Zheng He of the Ming Dynasty preserved shipwrecks rattan furniture, these rattan furniture have confirmed the level of development of China at that time. In the existing fine of Ming and Qing furniture, there are also a rattan chair seat.

2015年6月24日星期三

Make plastic molds

On the development and utilization of vine has a long history. Before the Han Dynasty, pupil furniture has not yet appeared, mostly people sitting and lying furniture seats, couch, among them woven plastic rattan molding seats, rattan seats and mats collectively bamboo mat, was a higher seat. "Yang Fei Arts", "chicken Albert Lam," "things Jiyuan up" and other clas there are records of rattan seats. Rattan seats was a relatively simple rattan furniture. Since the Han Dynasty, due to the development of productive forces, enhance the technological level of rattan,plastic container molding our increasing varieties of rattan furniture, rattan box, rattan screens, cane and rattan handicrafts vessels have appeared.

2015年6月20日星期六

Thin wall injection molding

1) Mainly used to produce the PVC window profiles,plastic rattan garden furniture mold plastic decorative plates and PVC

foam profiles

2) Use frequency conversion for speed regulation

3) Has super-taper twin-screw extruder with temperature controlling instrument in the screw core

4) Saves power by 30% - 40%

5) The rigid gear surface of the reducer can be operated continuously for a long

time without trouble

6) Operation and mold changing are smooth and steady

7) Long usage life

8) Can produce steel plastic profiles by changing the wood imitation foaming profile

mold, combines with one set of steel liner conveying devices

foam profiles

2) Use frequency conversion for speed regulation

3) Has super-taper twin-screw extruder with temperature controlling instrument in the screw core

4) Saves power by 30% - 40%

5) The rigid gear surface of the reducer can be operated continuously for a long

time without trouble

6) Operation and mold changing are smooth and steady

7) Long usage life

8) Can produce steel plastic profiles by changing the wood imitation foaming profile

mold, combines with one set of steel liner conveying devices

2015年6月16日星期二

Garden plastic chairs mold

Please do not pay before we quote you .The picture and prices shown are just for exhibition and display of our production .injection moulding companies So please feel free to send us 3D drawing with STL/IGS/STP file and your product description. We have the magic to turn it into real products,and then we will give you a quotation .If you have any enquiry,please contact

Packaging Detail:customed or cartonDelivery Detail:in 10 days

ABS Plastic Injection Moulding Parts

1.Material:PVC and ABS,PP

2.High quality

3.Standard:ISO9001,UV,U

ABS Plastic Injection Moulding Parts

Material:Rigid PVC and ABS,PP,PS,

Plastic Injection Molding Parts

Plastic Moulding/Molding parts

Plastic injection parts

plastric injection machine moulding parts

Plastic Auto Marks for Cars/Plastic injection moulding parts

Plastic Injection Moulding Car Products/Parts

Packaging Detail:customed or cartonDelivery Detail:in 10 days

ABS Plastic Injection Moulding Parts

1.Material:PVC and ABS,PP

2.High quality

3.Standard:ISO9001,UV,U

ABS Plastic Injection Moulding Parts

Material:Rigid PVC and ABS,PP,PS,

Plastic Injection Molding Parts

Plastic Moulding/Molding parts

Plastic injection parts

plastric injection machine moulding parts

Plastic Auto Marks for Cars/Plastic injection moulding parts

Plastic Injection Moulding Car Products/Parts

2015年6月14日星期日

Plastic rattan garden furniture mold

MASTER plastic rattan garden furniture is one of the world's oldest breed of furniture, first proposed by the European merchant in the 17th century into Europe. Series of baskets with rushes people found in Egypt,garden plastic chairs mold dating back to its 2000 BC, and in the ancient Roman murals often seen sitting in a wicker chair portrait of courtiers adults. In ancient India and the Philippines areas, people on the selection of cane to produce a variety of furniture, or cut into very thin and flat rattan cane, edited into a variety of patterns, so back, do kitchen door or rattan .

2015年6月12日星期五

Mold making

Your Home and Outdoor Rattan Furniture Maintenance:

Rattan, in the form of a material for manufacturing,is highly valued for its adaptability, strength, and longevity. Its gorgeous looking smooth texture is by natural means in the position to endure a great deal whilst left alone to have to deal with the elements, in every weathers. Sure the quality of the rattan employed is a great ingredient,plastic injection toy mould but rattan furniture could certainly go on for many, many years, nevertheless even the best high quality rattan will require to cared for in the proper way for it to last for as many years as it can. If you do have outdoor rattan fixtures or possibly a indoor rattan set, presented here are the primary cleaning methods you should consider and employ to maintain and care for your rattan pieces best.

Rattan, in the form of a material for manufacturing,is highly valued for its adaptability, strength, and longevity. Its gorgeous looking smooth texture is by natural means in the position to endure a great deal whilst left alone to have to deal with the elements, in every weathers. Sure the quality of the rattan employed is a great ingredient,plastic injection toy mould but rattan furniture could certainly go on for many, many years, nevertheless even the best high quality rattan will require to cared for in the proper way for it to last for as many years as it can. If you do have outdoor rattan fixtures or possibly a indoor rattan set, presented here are the primary cleaning methods you should consider and employ to maintain and care for your rattan pieces best.

2015年6月8日星期一

Plastic rattan garden furniture mold

MASTER Engineering and Design Team does best: finding innovative and creative solutions to help speed customers’ injection molded products to market.

The team uses project management through out the design process to document customer specific requirements and integrate them into the mold product design.

Using parametric fundamentals of plastic injection mould design,plastic injection mold makers the team creates tool design models that have complete associativity throughout all of the different components of an assembly. This means that both major and minor changes to a product can be made and reviewed with the customer through all stages of design and build of a precision plastic mould. Design changes are communicated electronically in real time to the machine programmers who are shaping the steel and can be communicated to customers via on-line web and video conferencing.

MASTER Engineers routinely recommend solutions to customers that can increase product performance, product lifecycle, reliability, and profitability both for MASTER, and for the customer.

The team uses project management through out the design process to document customer specific requirements and integrate them into the mold product design.

Using parametric fundamentals of plastic injection mould design,plastic injection mold makers the team creates tool design models that have complete associativity throughout all of the different components of an assembly. This means that both major and minor changes to a product can be made and reviewed with the customer through all stages of design and build of a precision plastic mould. Design changes are communicated electronically in real time to the machine programmers who are shaping the steel and can be communicated to customers via on-line web and video conferencing.

MASTER Engineers routinely recommend solutions to customers that can increase product performance, product lifecycle, reliability, and profitability both for MASTER, and for the customer.

2015年6月2日星期二

Water purifier molding

First, you will want to clean the cushion covers (if any) on your resin furniture. Remove the cushions from the cushion covers if possible and set the cushions aside. If you are using Patio Productions cushion covers,garden plastic chairs mold great! All of our cushion covers are a nylon fabric or Sunbrella, so they are easy to clean. Loosen the dirt on the cushion covers with the soft-bristle brush.If you haven’t already done so, you should watch this video about Sunbrella Fabrics. You’ll be an instant believe after you watch it!

2015年5月29日星期五

Toilet seat mold

Includes: regular cleaning of outdoor furniture, cleaning outdoor furniture Mildew is actually a plant that grows best in hot, MASTER Water purifier molding humid summer weather; it's a form of mold. The way to clean mildew from wicker outdoor furniture is with a hose or Plastic mesh furniture can be a little time consuming to clean, too.

2015年5月25日星期一

Chair mould

With plastic rattan shape with needle holes in between, this is the

most complex for injection molds. We have such plastic rattan chair

molds at site. For this kind of plastic rattan chair molds, on mold

steel for cavity or core, we suggest to use DIN1.2738 for molding. Also

such molds need very high precision machine tooling for the rattan

shape, to avoid future spurs on the small holes. And also the mold steel

need to be good strength for shut off areas for holes molding. With

another rattan shape without holes or with big holes, the mold would be

not so complex and would be easier.

With our rich experience on plastic rattan furniture molds making, we can support you with superior design, tooling and prompt delivery times. So if you have any project related for plastic rattan furniture molds, pls do not hesitate to contact with me.

With our rich experience on plastic rattan furniture molds making, we can support you with superior design, tooling and prompt delivery times. So if you have any project related for plastic rattan furniture molds, pls do not hesitate to contact with me.

2015年5月22日星期五

Thin wall moulding

For plastic rattan furniture molds, our company have made for plastic

rattan storage box molds, plastic rattan chair molds with arm or without

arm, plastic rattan drawer system molds, plastic rattan table molds,

plastic rattan tote molds, plastic rattan basket mold, mold making laundry container molds and so on. According to different rattan shape,

the mold cost is also different, and we suggest customers with suitable

mold steels.

2015年5月18日星期一

Thin wall injection molding

For different plastic furniture molding suppliers, in order to catch consumer eyes, the investors need to improve and promote their products very often to occupy the markets. In year 2014, more and more customer choose to make plastic rattan furniture molds compared before, this make final product more attractive compared with plain surface.

For plastic rattan furniture molds,pvc pipe fitting mould our company have made for plastic rattan storage box molds, plastic rattan chair molds with arm or without arm, plastic rattan drawer system molds, plastic rattan table molds, plastic rattan tote molds, plastic rattan basket mold, plastic rattan laundry container molds and so on. According to different rattan shape, the mold cost is also different, and we suggest customers with suitable mold steels.

For plastic rattan furniture molds,pvc pipe fitting mould our company have made for plastic rattan storage box molds, plastic rattan chair molds with arm or without arm, plastic rattan drawer system molds, plastic rattan table molds, plastic rattan tote molds, plastic rattan basket mold, plastic rattan laundry container molds and so on. According to different rattan shape, the mold cost is also different, and we suggest customers with suitable mold steels.

2015年5月14日星期四

Plastic mold manufacturer

MASTER plastic rattan garden furniture set 8PC Rattan sofa set for your cozy and relaxing living experiece and taste the beauty of nature garden plastic chairs mold

A-Material: Imitated PE rattan/wicker incorporated with high quality Alum frame

1) Frame: Powder-coated, light, strong and rust-resistant aluminum

Tube thickness: 1.2mm 1.5, 1.8mm

Circle Diameter: 28, 25, 22, 19, 16mm or customized

Square Diameter: 50*50, 40*40, 25*25, 20*20, 30*19, 15*15mm or customized

2) Rattan: On-recycled PE Rattan, durable and UV resistant

Flat rattan width: 6, 8, 10, 12 mm.

Round rattan diameter: 3mm.

Rattan color available: Charcoal, dark brown, chocolate, cream, beige, ect.

3) Cushion and pillows: 180g-250g waterproof polyester with zipper.

Sofas, beach chairs, sun beds and lounge: With 8cm thick cushions usually

4cm thickness for the chairs.

The regular size of pillow: 45*45cm.

Color is optional.

4) Table Glass: 5mm or 8mm tempered glass top, safe and strong.

A-Material: Imitated PE rattan/wicker incorporated with high quality Alum frame

1) Frame: Powder-coated, light, strong and rust-resistant aluminum

Tube thickness: 1.2mm 1.5, 1.8mm

Circle Diameter: 28, 25, 22, 19, 16mm or customized

Square Diameter: 50*50, 40*40, 25*25, 20*20, 30*19, 15*15mm or customized

2) Rattan: On-recycled PE Rattan, durable and UV resistant

Flat rattan width: 6, 8, 10, 12 mm.

Round rattan diameter: 3mm.

Rattan color available: Charcoal, dark brown, chocolate, cream, beige, ect.

3) Cushion and pillows: 180g-250g waterproof polyester with zipper.

Sofas, beach chairs, sun beds and lounge: With 8cm thick cushions usually

4cm thickness for the chairs.

The regular size of pillow: 45*45cm.

Color is optional.

4) Table Glass: 5mm or 8mm tempered glass top, safe and strong.

2015年5月3日星期日

Injection molding is a plastic thermo-physical properties of the material from the hopper into the barrel, the barrel outer ring heated by the heating, the material is melted in a cylinder that has the power under the external action of a Plastic injection mold makers rotating screw, the role of the material in the screw down along the groove forward transport and compaction, the material is heated and a screw cut out the dual role gradually plasticized, melted and homogenized, when the screw is rotated, the material groove friction and shear forces in the the role, the molten material onto the screw head, at the same time, the screw at the back reaction material, the screw head forming material storage space, complete plasticizing process, then screw in the injection cylinder piston thrust after the next action, high speed, high pressure, the material storage chamber through a nozzle melt injected into the MASTER plastic molding factory , the cavity in the melt through packing, cooling, curing stereotypes, the role of mold clamping mechanism open mold, and top of the device by setting a good product from the mold to the top of the falls.

2015年4月23日星期四

The garden chair

The garden chair is known for its old and simple, although for many centuries, is a common condition. The garden chair is present, since at least the early dynastic period. They were covered with cloth or leather, wood, were much lower than today's MASTER garden plastic chairs mold , the chair seat, sometimes only 25 cm high. In ancient Egypt the chair seems to have greatly enriched and brilliant. The old ebony and ivory carved and gilded wood, they were covered with MASTER china plastic injection molding , gorgeous pattern and legs beast or captured the figures, said support. In general, the higher the rank of the person, higher, more beautiful he is sitting on the chair, the greater glory. In the national important occasions he sat on the throne, often a small stool in front of the far away with it.

2015年4月20日星期一

Garden furniture, by definition, is placed in the garden furniture, outdoor furniture also belongs. Now, with more and more people's living standards, live in villas or manor of people will carefully design your own garden, it will inevitably and ultimately, MASTER thin wall moulding to set up a garden furniture for family and friends in this recreation! So, when the arrangement of garden furniture, which it needs to pay attention to? Let's look at what classification of garden furniture. Garden furniture categories are: high bar MASTER chair mould , dining tables and chairs, coffee tables and chairs series, leisure chairs, deck chairs, etc., garden furniture classification generally is that, in the arrangement of the garden, but when these garden furniture to good design and placement.

2015年4月16日星期四

Make plastic molds

Make plastic molds

Make plastic molds is a tool for the production of plastic products. It consists of several groups of components parts, this combination successful mold cavity. China plastic injection molding , the injection molding machine mold clamping, the molten plastic is injected into the mold cavity, and cooling and sizing in the cavity, and then the upper and lower split mold, the top of the system via the top of the article from the mold cavity leaving the die, and finally the mold is closed the next injection, the entire injection cycle is carried out.

2015年4月7日星期二

Add some garden furniture for your garden

plastic rattan garden furniture

2015年4月2日星期四

MASTER plastic rattan garden furniture

MASTER plastic rattan garden furniture

2015年3月26日星期四

Injection molding process

Injection molding process

Injection temperature is an important factor affecting the injection pressure. Injection molding machine cylinder 5 to 6 heating section, each material has its appropriate processing temperature (processing temperature can refer to the detailed data provided by the material supplier). Injection temperature must be controlled within a certain range. Temperature is too low, poor melt plastics, affecting the quality of molded parts, increasing the difficulty of the process; the temperature is too high, the raw material is easy to break down. In the actual china plastic injection molding , the ake plastic molds temperature is often higher than the cylinder temperature, the higher the value of the injection rate and properties of the material concerned, up to 30 ℃. This is because when the melt is subjected to shear Gate passage and generate heat caused. In making mold flow analysis can be used to compensate for this difference in two ways, one is trying to measure the melt temperature when air injection, and the other one is modeling the nozzle is also included.

2015年3月17日星期二

MASTER plastic rattan garden furniture

MASTER plastic rattan garden furniture

MASTER plastic rattan garden furniture mold, plastic processing industry and plastic molding machine supporting, giving plastics to complete configuration and precise dimensions of the tool. Because many plastic varieties and processing methods, structural plastic molding machines and plastic products also of sophistication varies, therefore, the type and structure of the garden plastic chairs mold is varied.A compression molding, extrusion, Custom injection moulding , blow molding, and low foaming modular plastic mold, which includes a variable combination of the die cavity by the board.

2015年3月6日星期五

plastic rattan garden furniture mold die manufacturing development trend of the market

In particular, most of the tools is the key part of the plastic rattan garden furniture mold or the member is multi-directional force, thereby increasing the isotropic steel, to improve toughness and ductility lateral, MASTER plastic rattan garden furniture mold can greatly improve the working life of the mold, which is alloy tool steel in recent years, one of the main direction of development.

In addition, to improve the purity of the alloy tool steel, alloy tool steel that reduce the content of harmful impurities are effective measures to improve the properties of steel, using a variety of refining process, the production of high purity steel, plastic rattan garden furniture mold steel mills are currently various metallurgical the main direction of efforts.

In addition, with the increasingly widespread application of standard mold, plastic rattan garden furniture mold standardization, commercialization of improved quality for steel products, different specifications, and delivery cycles and higher requirements.

Therefore, injection moulding companies according to the needs of the domestic iron and steel enterprises mold and die manufacturing development trend of the market, pay close attention to research and development of high-precision, high toughness, corrosion resistance, high-quality new varieties of mold steel, so that made the hot and cold die steel reached the world's.

2015年3月2日星期一

plastic rattan molding from the gap between the needs of users

Since the eighties, plastic rattan molding has entered a period of rapid development, which greatly promoted the production and application of technological advances in tool steel, MASTER plastic rattan molding through the introduction of advanced equipment and technology, is capable of producing a variety of high-quality tool steel, domestic steel mold and quality has made great progress and improve. However, the aggregate level, the country is still relatively backward steel mold, especially for the manufacture of high-grade steel mold, still in use imported steel, compared with the international advanced level, mainly in the following gaps:

1) die steel varieties, specifications incomplete, more low-level, less high-grade. High-quality, high-performance tool steel varieties less. In terms of species, not yet formed plastic, glass, building materials, ceramics and other special mold steel series. Flat steels, modules, relatively low proportion of fine material products, utilization of steel about 10% lower than in other countries. To meet the manufacture of large, sophisticated, complex, requiring high life of the mold, thin wall injection molding the overseas development of pre-hardened steel, while the domestic steel basically stay in the annealing stage, or hot-rolled state delivery, and long lead times, which is China's home appliance industry the main reason a lot of die steel imports.

2) a lower degree of specialized production mold steel. Quality steel, poor performance stability, poor visual quality. Chinese scattered in dozens of die steel production, most of the manufacturers of production technology and equipment is not complete, especially in the rear of the process, processing equipment behind, thereby constraining domestic steel mold improve improve quality and performance.

3) die steel supply and marketing channels remain open. plastic rattan molding manufacturing, mostly single or small batch production, and varieties of steel required, specifications, a small number, the demand for timely delivery of industry characteristics, and mass production of metallurgical plant contradictory. garden plastic chairs mold May at any time resolve the problem of foreign retail stores through steel. China in recent years there have been some agents, steel shop and other intermediate sales cycle, but in the mold steel sales of service and level of foreign advanced level there is a gap, affecting the promotion and application of domestic steel mold. For example Bohler - Uddehum 100,000 users worldwide, mostly engineers, guiding users.

It is noteworthy that matter, China's mold quality and service, from the gap between the needs of users is quite large, so we had a lot of "prefer a higher price abroad, do not want to buy a home at a low price" is not a normal phenomenon. Domestic and international prices of some steel mold is shown in table 1. From the table, than the domestic price of imported steel prices 3-6 times higher, reflecting the backwardness of China's mold steel from the price gap between the same grades

2015年2月26日星期四

Create a plastic rattan garden furniture out of diseconomies

Unlike other industries, mold is a single-piece production, industry-specific processing, which determines the different mold species require different processing equipment. If in order to win orders, to meet the different needs of users of different products, you need to purchase different equipment, MASTER plastic rattan garden furniture mold but often the old processing bottleneck is resolved, has produced a new bottleneck, and this processing bottleneck is due to the processing of different varieties and constantly changing, sometimes four coordinate line cutting is not enough, and sometimes they piled live electrical pulse, sometimes rough or heat treatment process became the "obstruction", and in this "obstruction" formation Meanwhile, plastic rattan garden furniture a large number of other high precision equipment also idle in the side.

Rarely is there such a phenomenon in Beilun, Huangyan, Shenzhen, Dongguan, Guangdong, Zhejiang and some mold companies. In these areas, some mold manufacturing enterprises, and not much production equipment, there are only some design resources and testing equipment, but their products in the market is very competitive. plastic rattan garden furniture mold are mainly used to obtain benefits through the division of labor among enterprises, promote enterprise development. After receiving their production tasks, will be very easy to buy in the neighboring businesses specializing in mold, guide posts, plastic rattan garden furniture guide sleeve and other standard parts, but also very easy to carry between them machining centers, CNC milling, wire cutting, plastic mould maker and other precision machinery collaborative process, so they are very low tooling costs, processing and production levels have greatly improved.

These areas have actually formed the aggregation effect of the industry, do die do some business to concentrate on the development and design of precision molds, do wire cutting, machining centers, electrical pulse, CNC grinding, heat treating, plating, standard parts production enterprises are all Secretary for his part, responsible for the precision machining of several or even a member. Benefits of doing so is to avoid too large a business investment, at the same time, they allow us to have a higher mold manufacture in terms of professional and technical standards, in addition to each other can form a complete industrial chain.

2015年2月16日星期一

plastic rattan garden furniture is to further expand

With the expansion and increase total production capacity, mold quality significantly improve the technological level, the current mold industry of digital technology, plastic rattan garden furniture and EDM, CNC machining technology has been widely used; MASTER plastic rattan garden furniture mold new technologies such as hot runner mold technology gas-assisted injection technology and cae technology gradually adopted, many companies have also introduced advanced mold design and manufacturing software. There are four mold companies were identified as provincial high-tech enterprises, injection mold maker the four companies undertake national and provincial Torch Program, 21 passed iso9001 certification. plastic rattan garden furniture National Science and Technology approved the "National Torch Plan Huangyan plastic mold industry base." Make plastic molds A full range of products and gradually improve the product level, reflecting the combined effect of a certain size. In sales, the plastic mold product sales accounted for only one-third within Taizhou, export scale is further expanded.

2015年2月12日星期四

plastic rattan garden furniture mold wide application of advanced technologies

plastic rattan garden furniture mold as early as the 50s of last century, was founded in Huangyan (ie Huangyan Mould Co., Ltd.), from the production of small, simple mold beginning, MASTER reaction injection moulding has now formed a plastic mold as the main product, both stamping die, die casting, casting production pattern mold.

In clusters, specialization, collaborative development model, a number of distinctive characteristics of the industry key enterprises to support the development of the whole industry: pvc pipe fitting mould Dow Group to produce television sets, home appliances and automotive plastic molds mainly the United States and more mold factory to produce air conditioning die-based, Zhejiang mold factory to produce automotive interior and exterior trim and medium-sized plastic molds mainly Huari Group to produce plastic rattan garden furniture mold based.

2015年2月8日星期日

plastic rattan molding market competition within the industry

Numerous plastic rattan molding products processing enterprises, the life plastic products accounted for 60%, both automobile and motorcycle plastic parts (Scooter various OEMs currently 70% of the plastic parts provided by Taizhou enterprise), building materials and plastic products , MASTER thin wall injection molding plastic packaging products, agricultural and fishing with plastic products, medical plastic products and other plastic products, toys and handicrafts. Living with plastic rattan molding technology content and low added value, scale enterprises began to gradually withdraw from the market with plastics from life, the main engineering plastic products for industrial use.

A typical example is the Yufeng Group. Like many companies, founded in plastic rattan molding production techniques from the lower levels of household plastic products beginning, plastic mold manufacturer then Taizhou of household plastic products production mushroomed developed, intensified market competition within the industry. Early 90s of last century, the group caught ordinary families and household appliances motorcycle popularity opportunities, has targeted the development of household appliances and motorcycle plastic parts manufacturing, production and sales companies. Recently, plastic rattan molding purchased a total value of 85 million yuan for the entire computer Haitian injection molding machine, the high-tech industry innovation and development of mechanical parts inside the machine for high-strength, wear-resistant plastic gears and other components become leap Group supporting manufacturers.

plastic rattan garden furniture mold Throughout the production and marketing activities, the city has formed a series of specialized division of labor system of plastic raw materials procurement, mold design and manufacturing, plastic products markets. City plastics processing industry has 75% of corporate purchasing new materials from raw material suppliers in the region, road and bridge, Huangyan has built a professional market, the implementation of delivery. Bridge held at the annual China Plastics Fair, at home and abroad have a certain visibility.

2015年2月4日星期三

plastic rattan garden furniture industry perspective

Over a decade ago, plastic rattan garden furniture to have these two resounding title: "plastic kingdom" and "Die town", plastic mold industry has become a pillar industry of the region. MASTER plastic rattan garden furniture mold A material from the Municipal Economic Commission, said: to the city's plastic manufacturer 9472, industrial output value 27 billion yuan, accounting for 10.6 percent of the city, accounting for a quarter of the province's plastics industry sales revenue. Of which 240 scale enterprises, plastic rattan garden furniture is the city's most promising pillar industries. plastic rattan garden furniture mold The city mold manufacturing sales revenue 3.85 billion yuan, accounting for 8% of the country.

plastic rattan garden furniture processing: from life to engineering plastic with plastic

Experts point out that industrial linkage plastic rattan garden furniture industry, plastic mould maker big, strong impetus, outgoing high, the development of plastic mold industry is conducive to stimulating the development of other sectors, to promote the adjustment of industrial structure. This is the advantage of the whole plastic mold industry lies.

订阅:

博文 (Atom)